Your Trusted Partner for Innovation

At Cyncly, we understand the unique challenges and opportunities within your industry. With decades of specialized experience, we provide practical, proven software solutions that empower businesses like yours to thrive in a rapidly evolving market. We are committed to being more than just a vendor; we are your strategic partner, dedicated to your success.

- Trusted by thousands of businesses worldwide.

- Decades of industry expertise.

- Pioneering AI-driven solutions for real-world impact.

Trusted by 70,000 businesses across 100+ countries

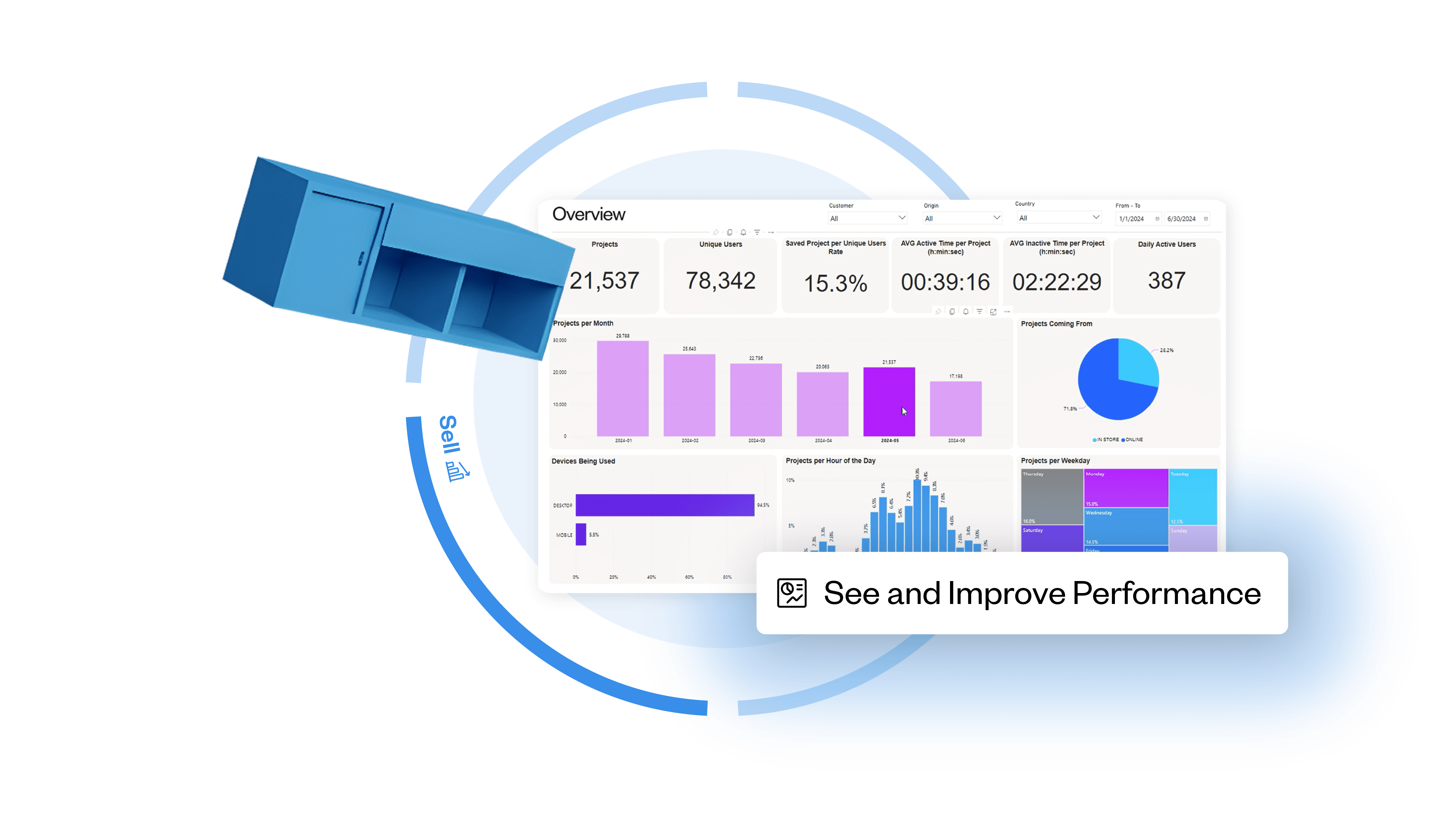

From boutique studios to global leaders, Cyncly delivers measurable results: faster time-to-market, higher conversion rates, and lower operational costs.

Seamlessly Connecting Your Entire Business Ecosystem

From the initial spark of an idea to the final installation, Cyncly provides the integrated solutions you need to manage every step with precision and control.

Empowering designers with intuitive tools for creative freedom and precision, ensuring every vision can be brought to life efficiently.

Optimizing production workflows, reducing waste, and ensuring quality with smart automation and streamlined processes.

Enhancing customer experiences and boosting conversions with personalized engagement and efficient sales processes that turn browsers into buyers.

Streamlining project management and ensuring flawless execution from start to finish, leading to satisfied customers and repeat business.

Explore our featured products

Ready to Transform Your Business?

Discover how Cyncly can help your business simplify complexity, digitize execution, and deliver connected customer experiences.