The Divian story

Divian is one of Hungary’s leading kitchen manufacturers, known for combining craftsmanship, technology, and efficiency. With manufacturing based in Szeged, the company produces around 10,000 kitchens annually, serving customers nationwide through a network of more than 400 resellers across the country.

As a company with deep experience in both manufacturing and retail, Divian has long understood that speed, precision, and design quality are equally essential. Customers today expect photo-realistic 3D designs and fast delivery, while dealers require tools that simplify complex workflows and reduce administrative errors.

To meet these needs, Divian turned to Cyncly’s Spaces Flex, a next-generation design and sales platform integrated with Insight, the company’s manufacturing system. Together, these solutions have transformed how Divian collaborates with its partner network, from first design to final delivery.

Divian long understood the value of 3D designs, and was the first Hungarian kitchen furniture manufacturer to provide 3D visual design equipment. Before adopting Spaces Flex, Divian’s retail partners used a design solution that required manual order entry between the design and manufacturing stages. Each project had to be recreated inside the production system, creating delays and opportunities for errors.

Given that Divian’s factory produces up to 300 cabinets per day, even a small mistake could disrupt production schedules or require costly rework. Manual data transfer also limited the company’s ability to provide customers with quick, accurate updates about their orders.

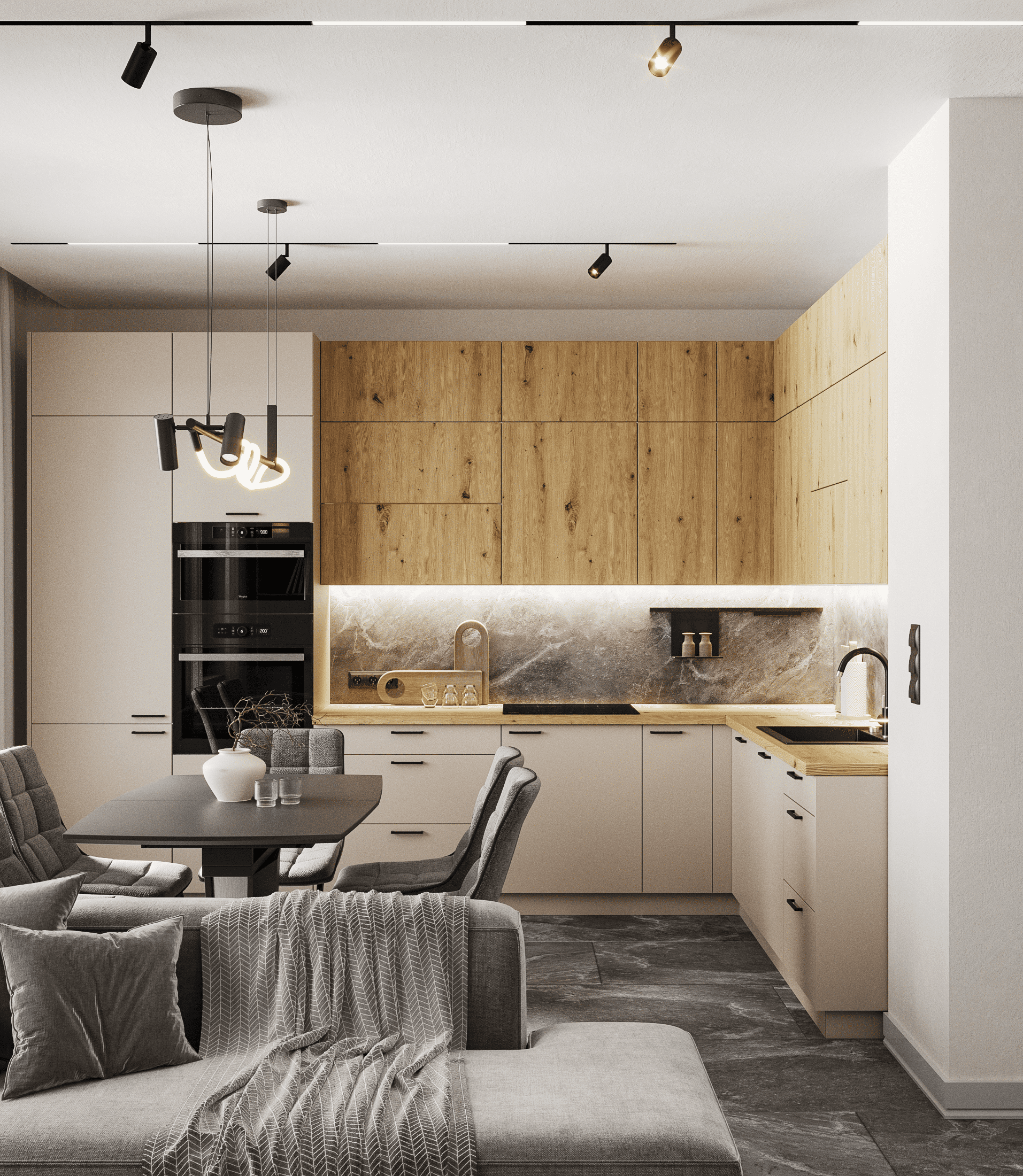

At the same time, customers increasingly expected high-quality 3D renderings as part of the design process — a standard Divian’s previous tools couldn’t always meet.

“Before, even small manual errors could cause major rework. We needed a connected solution from sales to manufacturing.”

To modernize the design and sales experience, Divian implemented Spaces Flex in 2024, replacing its previous Virtual Planner tool. Working closely with Cyncly, Divian customized the software to include its full catalog of cabinets, finishes, and accessories, ensuring a perfect match between the digital design and the physical product.

The company began with a pilot involving 5-10 partner shops, gathering feedback and refining the catalog. Once proven, the rollout expanded to 70 retail locations across Hungary.

Training was straightforward: most kitchen designers became proficient after just two to three hours of instruction. Their live training was supported by Teams-based group sessions, recorded tutorials, and online resources.

Spaces Flex is now fully integrated with Insight, Divian’s manufacturing platform, so every design automatically translates into a precise bill of materials and production order. What customers see on-screen in 3D is exactly what the factory produces.

This end-to-end connection has also standardized communication across departments.

“The whole company now speaks the same language — from sales to factory.”

Within months of implementation, Divian saw measurable results across sales, customer experience, and production efficiency.

Sales are up to 50% faster. Retail consultants can design kitchens live with customers in the shop as a collaborative experience, incorporating feedback directly into the final design. Retail partners often complete projects in just one to two hours, enabling the customer to decide and purchase in a single meeting.

As a result of the live design process, high quality renders and fast design turnaround, Divian retail partners using Spaces Flex have achieved a conversion rate of up to 75%.

Customer satisfaction has improved. Shoppers receive their 3D renders immediately in-store, followed by automated emails with order details, pricing, and delivery dates, creating transparency and trust.

Manufacturing error rates have dropped below 1%. Automated checks ensure complete design consistency, from hinge direction to color coordination, before a project reaches production.

Orders flow instantly to manufacturing. Once a design is finalized, it’s sent directly to the factory. In some cases, production begins within minutes.

And factory productivity has increased. With integrated data and better planning, Divian has been able to optimize production so efficiently that during summer months, teams even enjoyed additional Fridays off without impacting output.

“It’s very important to have a tool that’s easy to use and eliminates errors. It ensures what the customer sees is exactly what we build.”

¿Qué beneficios puede esperar?

Looking ahead

Divian continues to view Spaces Flex as a strategic platform for future growth. The company plans to expand its digital ecosystem by launching consumer-facing AI-powered design tools that allow homeowners to configure their own kitchen designs. Using the measurements of their kitchen and choosing their preferred style, consumers will be able to create their own designs easily, making them farther down the sales cycle when they engage a Divian retail partner.

This self-service capability will also help Divian collect leads and track campaign performance across social media channels to better understand consumer behavior and preferences.

At the same time, Divian is investing in its brand store network, beginning with a flagship showroom in Budapest, where customers can experience the company’s kitchens firsthand — supported by the same immersive Spaces Flex design technology used by its partner dealers.

What Divian says

“Spaces Flex is our most important marketing tool. It allows our shops to create beautiful, accurate 3D kitchen designs with customers in real time.”

“Our goal is to give customers as many tools as possible — simple, precise, and inspiring — while maintaining full control over quality and consistency.”

Zoltán Varga, Executive Director of Divian