In residential window and door manufacturing, variation is constant, but it should not stand in the way of growth.

Residential window and door manufacturers work in a fast-moving market where every order feels different. You balance margin control, short lead times, and high volumes while coordinating between profile suppliers, flat glass fabricators, and a mixed network of dealers, distributors and direct in-home selling with their own ways of quoting and ordering.

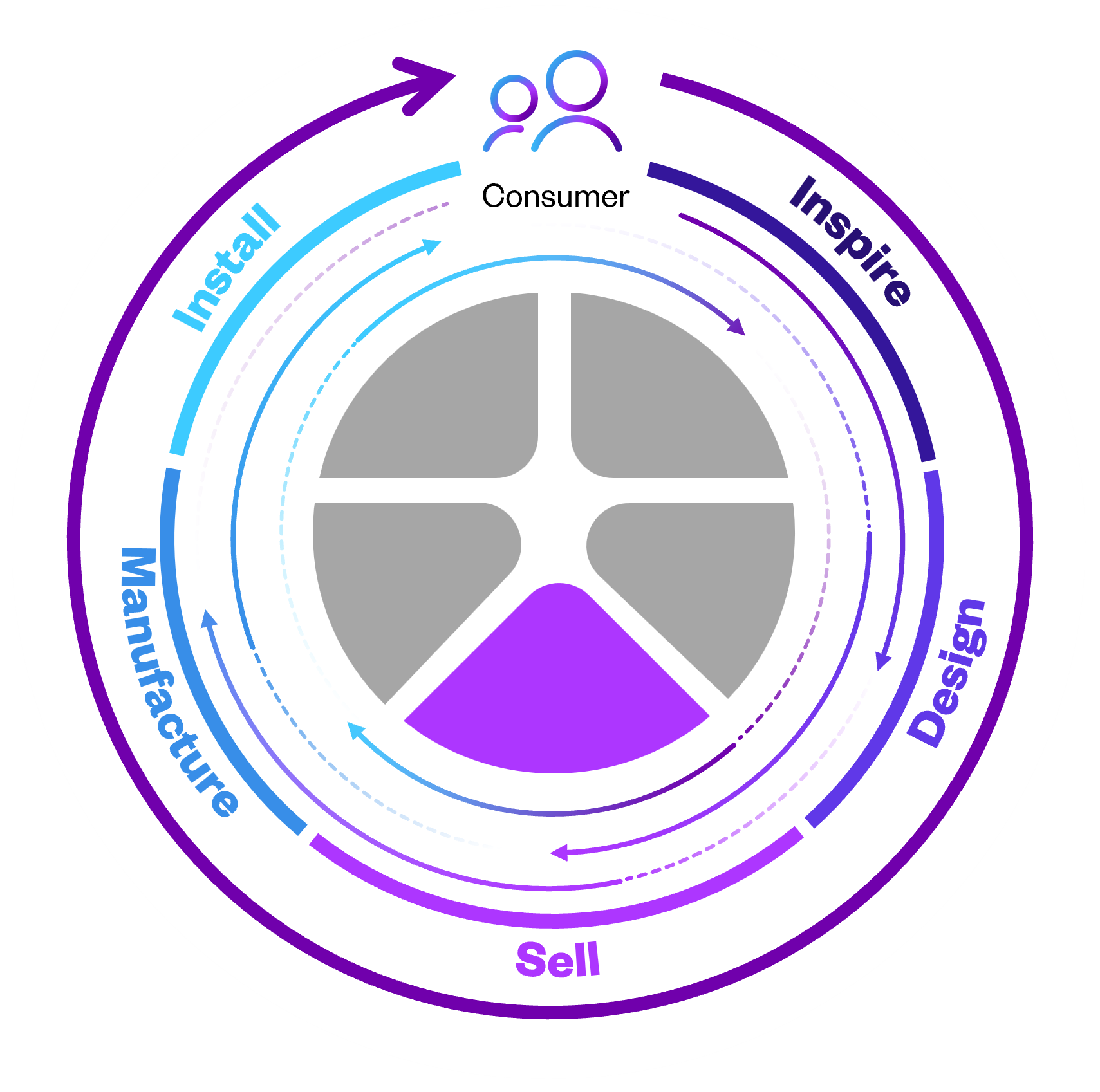

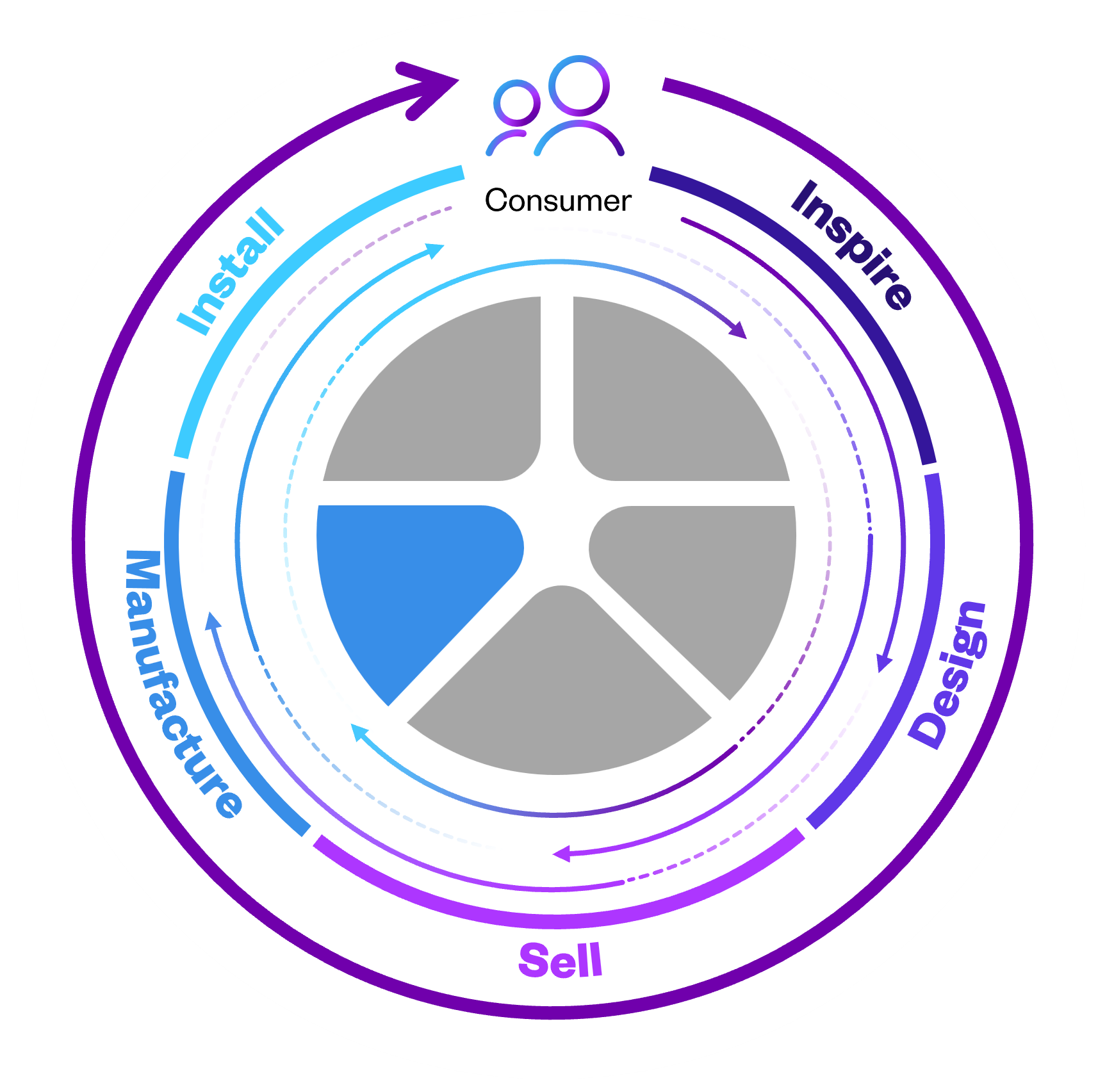

To stay competitive, you need software that connects inspiration, quoting, production, and installation in one place, so teams work faster, make fewer mistakes, and protect margins even as your product mix becomes more varied.

Solving the challenges of residential window and door manufacturing

Give homeowners, dealers, contractors, and distributors an easy way to explore styles, options, and prices before they commit. Help them make confident choices that already match your production rules.

- B2B eCommerce: Online configurators that present your catalog

- In-home sales experience: Share your catalog with top of the market in-home selling tools customers already use

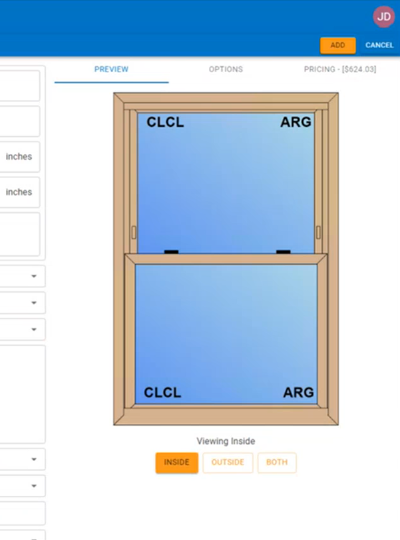

- Visualization: Visualize their windows, mulled units, bays and bows, and entry doors as single units in real-time

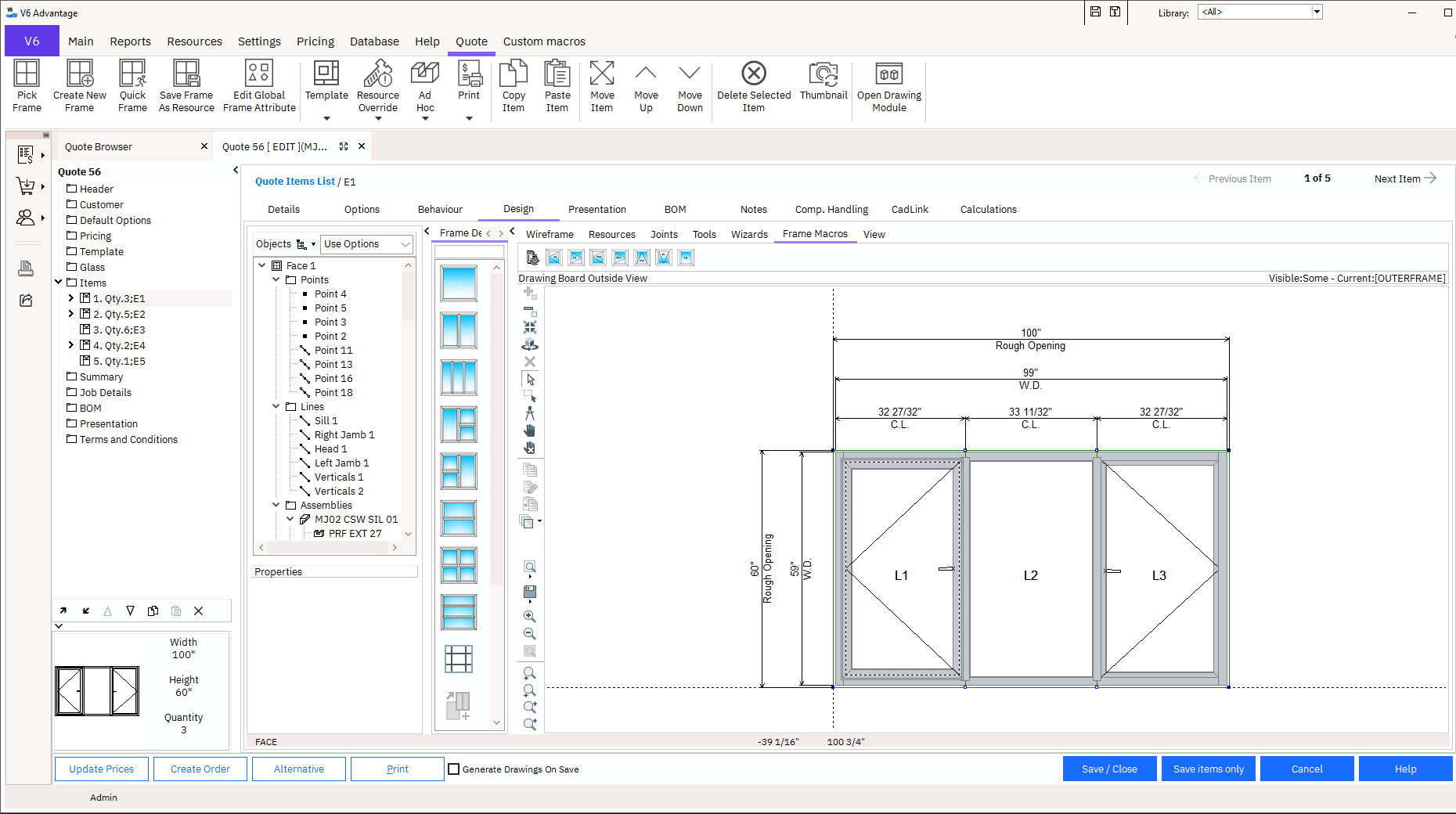

Turn customer choices into precise, production ready units. Keep every configuration within your rules so engineering does not need to review every order.

- Manufacturing Constraints: Rule based configuration that prevents invalid sizes, options, and mull combinations

- Visualization: High quality renders that set clear expectations for homeowners and dealers

- Multi-Window Designs: design multi-window or entry doors with visuals that update with decisions

Sell more without adding more data entry staff accurately and in line with your margins. Make it simple to move from a kitchen table conversation to a confirmed order.

- Pricing: Up to date pricing for glass type, makeup, and CNC machining

- Order Imports: Receive orders via EDI files or uploads from B2B eCommerce

- Dynamic BOM: Automated bill of material generation for costing and production requirements

- Required Dates: Shortest lead time calculation based on product mix, capacity, and sourcing (glass, shaped frames, etc.)

Run residential production with predictable lead times and reliable quality, even as customization grows. Give planners and shop floor teams the data they need to keep lines moving.

- Production management to optimize batch sequences that optimizes batches across sizes, options, frame types, and production bins

- Material optimization reduces scrap and boosts yield for both lineal and annealed glass lines

- Warehouse management for accurate inventory

- Machinery integration across mixed vendors and legacy equipment

Deliver on-time and accurately reducing material handling loading and unloading trucks. Keep customers informed and maintain reliable service quality.

- Route Management: Build regular routes to automate route creation

- Delivery App: Go paperless with increased accountability the field

- Return Material Authorization (RMA): Incorporate pickups, rework, and remakes into your daily process with customer transparency