Modern furniture and cabinet manufacturing demands more

Consumers expect personalized designs. Lead times are tighter. And sales now happen across showrooms, online platforms, and retail partners.

To keep up, furniture and cabinet manufacturers need connected systems that simplify complexity, not add to it.

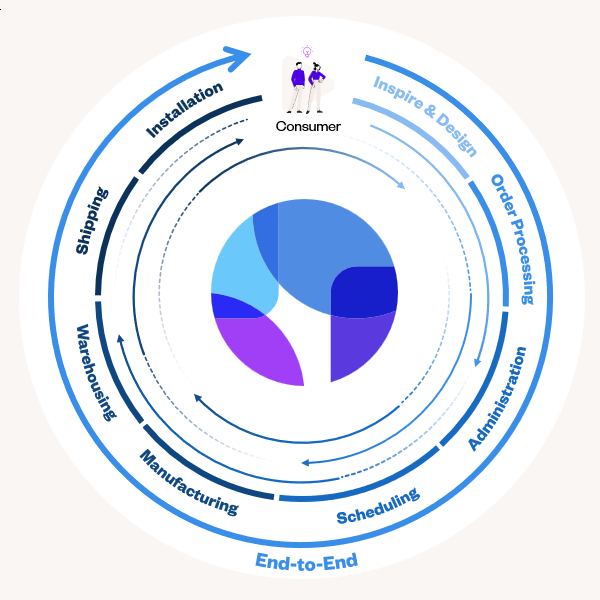

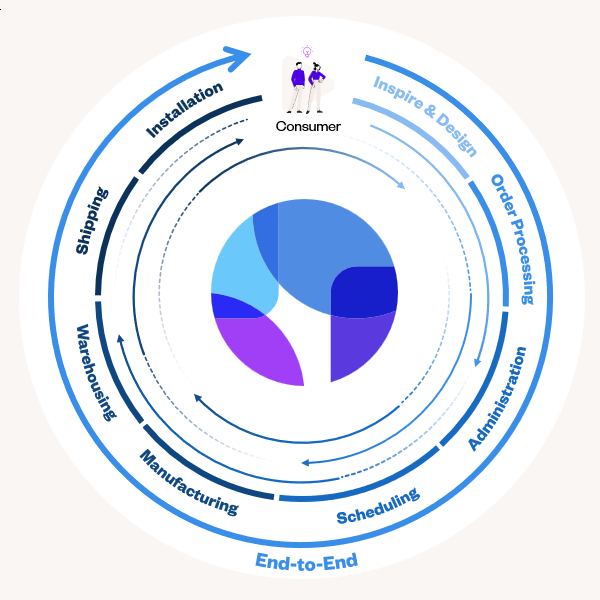

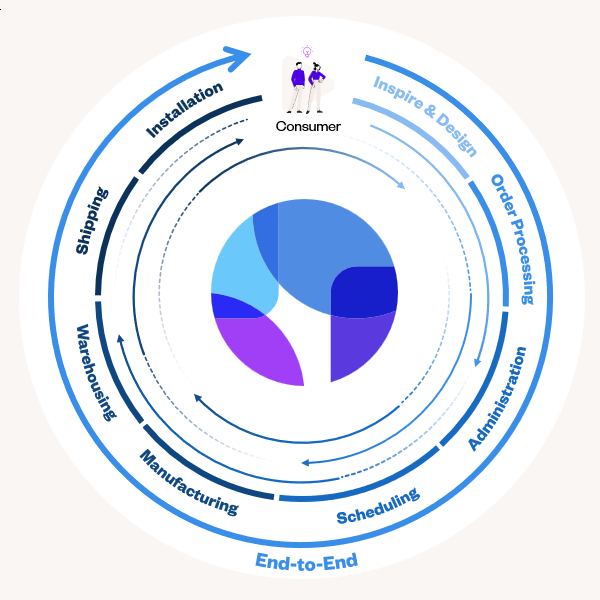

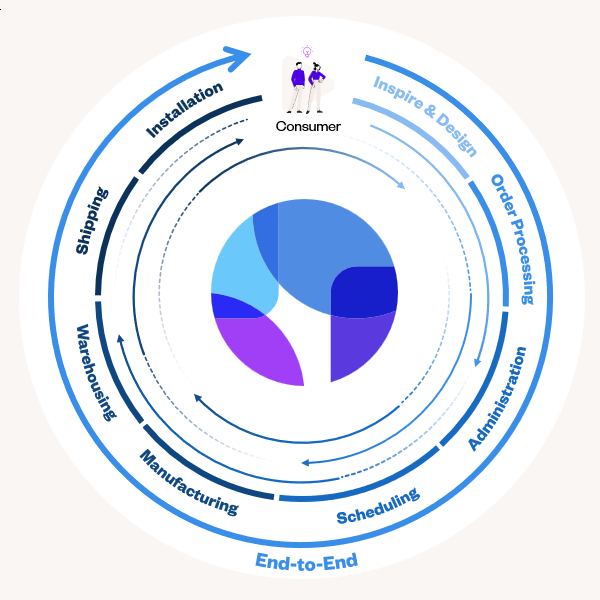

Cyncly brings your entire operation together - from inspiration and design through to production and installation.

Meeting modern manufacturing demands

Speed and precision are the new minimum. Whether you produce custom kitchens or high-volume furniture, success comes from connecting the dots across your business.

That means capturing demand with accuracy, managing thousands of product variations, and delivering with confidence, every time. We help you build a resilient, end-to-end operation that turns complexity into control.

Client partners in the furniture industry

Built to lead the next era of furniture manufacturing

Whether you're scaling, shifting go-to-market strategy, or increasing product personalization, we give you the foundation to adapt with confidence.

Give customers and dealers a rich visual experience that turns inspiration into action.

With immersive online galleries, room planners, AR previews, and tailored design catalogs, you can showcase your full offering and guide buyers to the right choices.

Omnichannel engagement becomes seamless, accurate, and trackable - from web to showroom.

Ensure design decisions are production-ready from day one.

Intuitive 3D design tools and advanced CPQ logic help teams generate accurate configurations, pricing, and BOMs.

By connecting design with engineering and product rules, you avoid rework, improve quotation accuracy, and set projects up for success from the start.

Automate quoting, order validation, and manufacturing prep with structured data that flows cleanly between systems.

Complex orders are instantly converted into manufacturing logic, reducing manual input and speeding up order cycles.

Sales teams, retailers, and planners work with the same data, minimizing friction and delivering better customer experiences.

Gain full control of the shop floor with connected scheduling, real-time IoT insights, and machine-level tracking.

Improve throughput and resource planning while reducing downtime, material waste, and manual work.

Whether you produce at scale or with high variability, you’ll maintain consistency, accuracy, and visibility across every plant and shift.

Final delivery should be seamless. Equip installation teams with mobile access to documentation, part tracking, and customer data so they arrive prepared.

Streamline coordination across shipping, warehousing, and job sites to reduce delays and ensure quality handoff.

The result: fewer errors, faster closeout, and a better customer experience.

Who we support

Whether you make kitchen cabinets, flat-packed furniture, or built-to-order commercial systems, we help you digitize production workflows, align departments, and deliver with precision.