CAPABILITIES

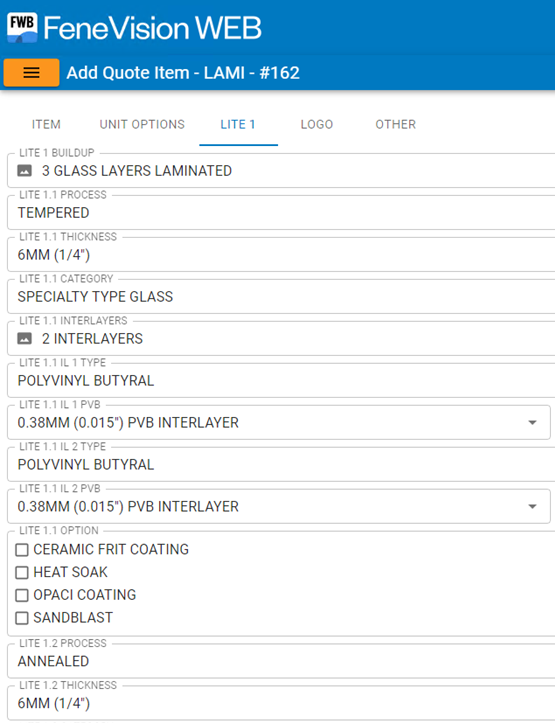

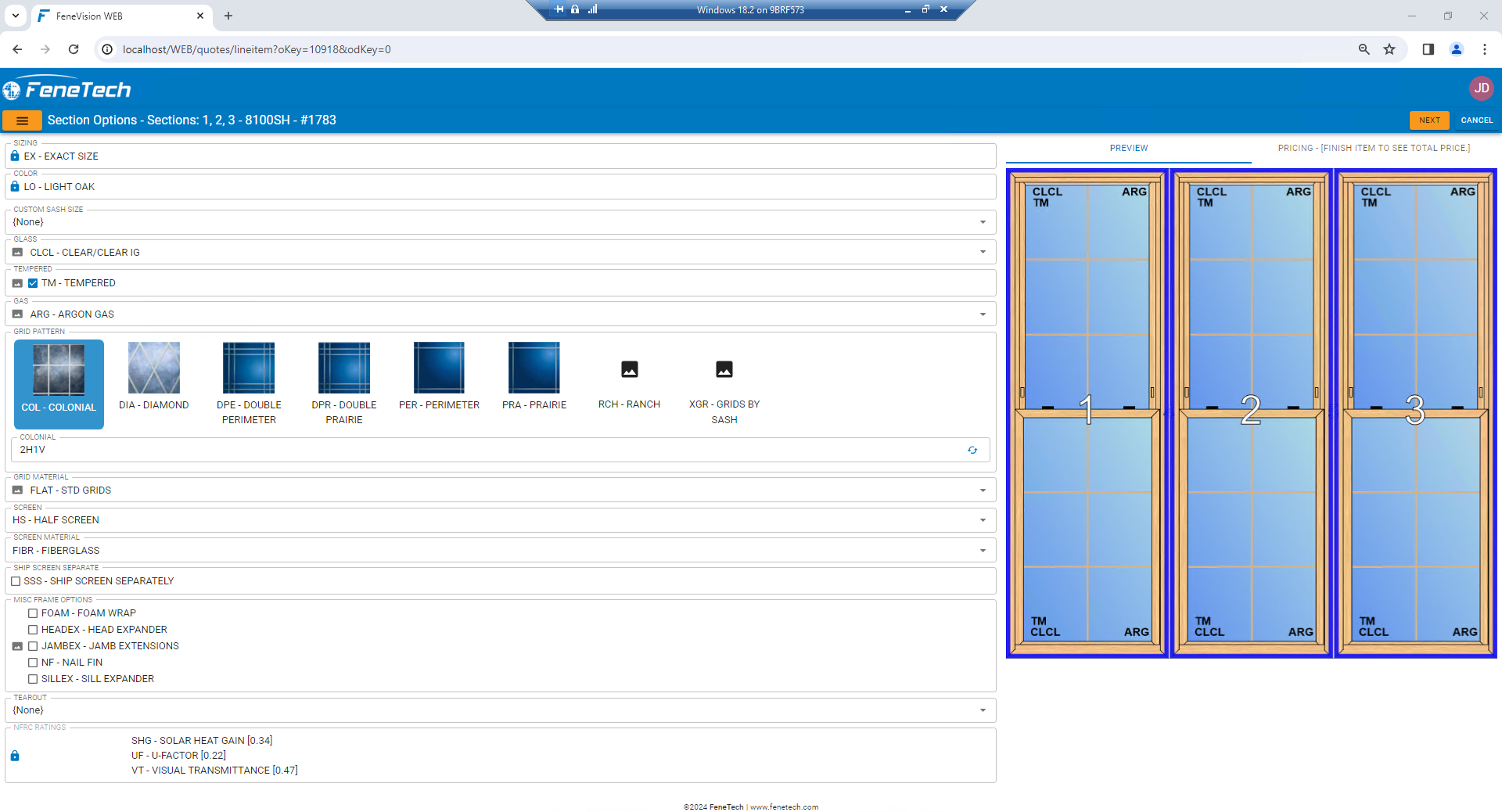

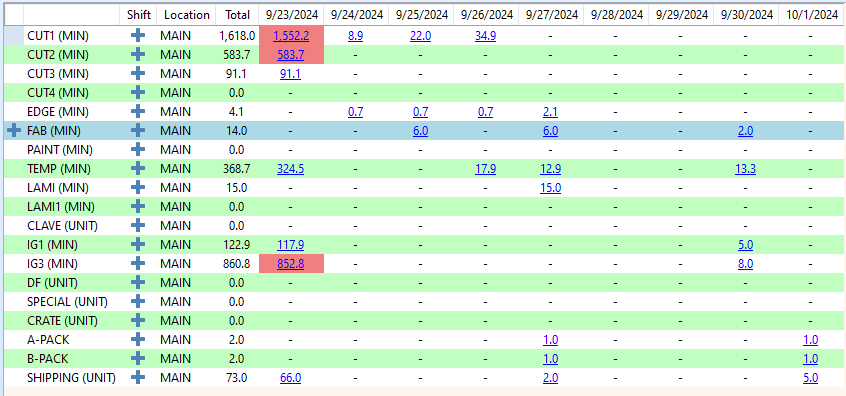

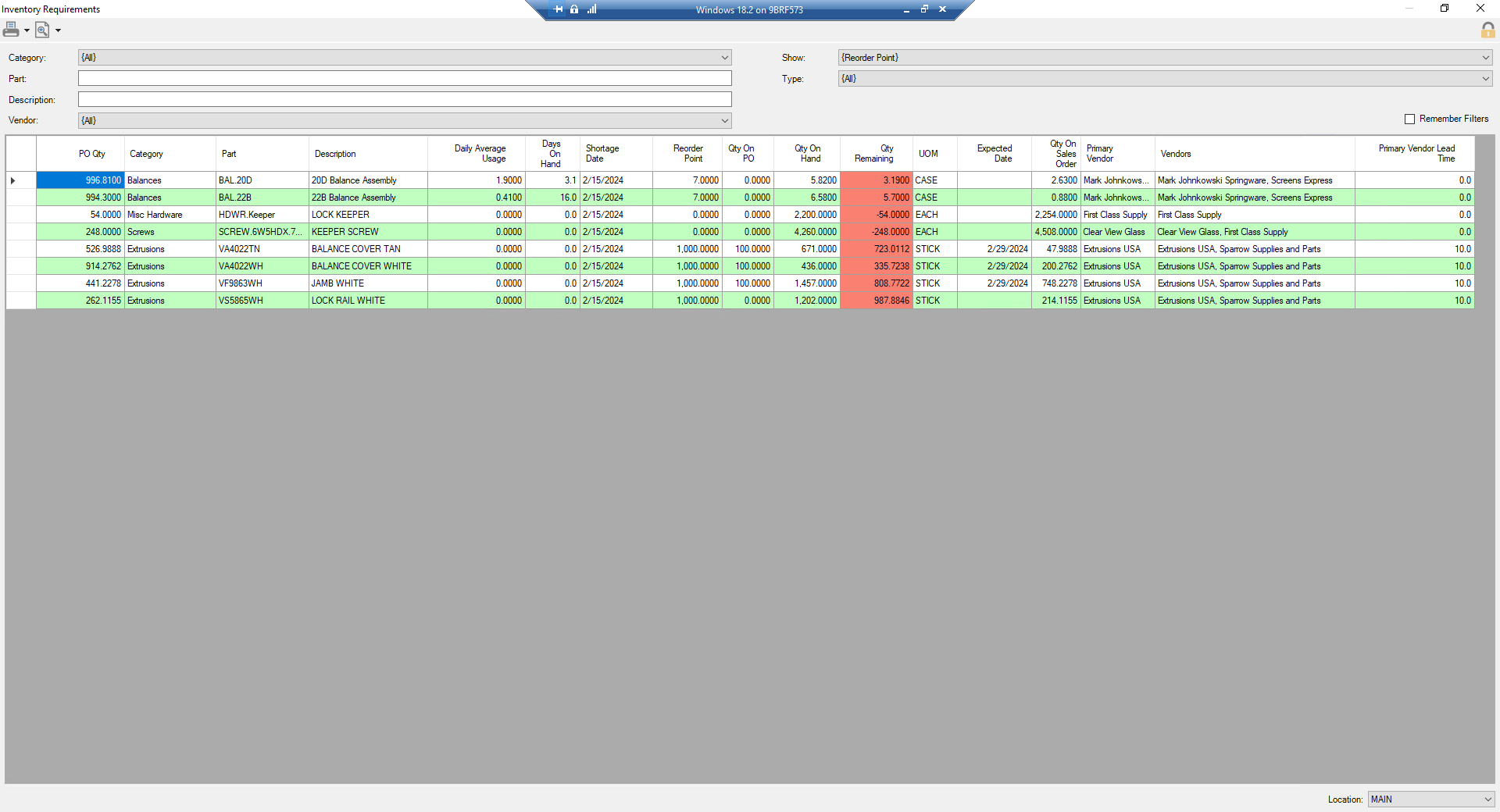

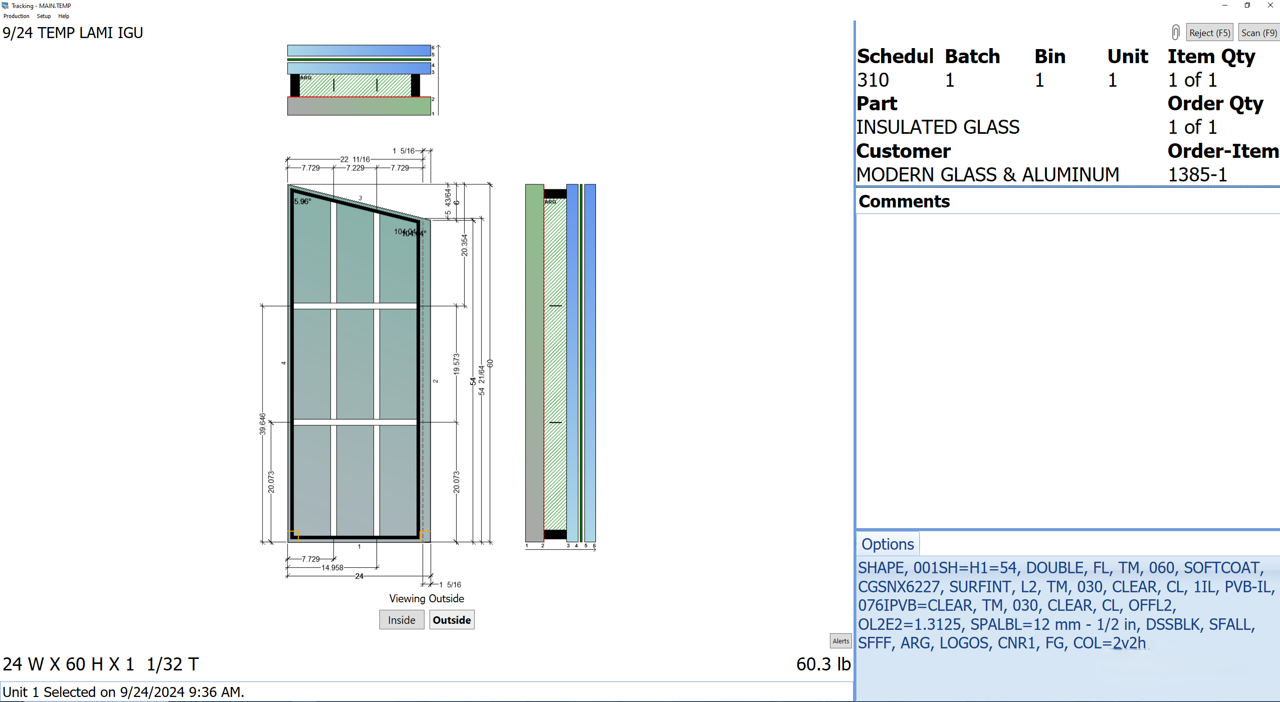

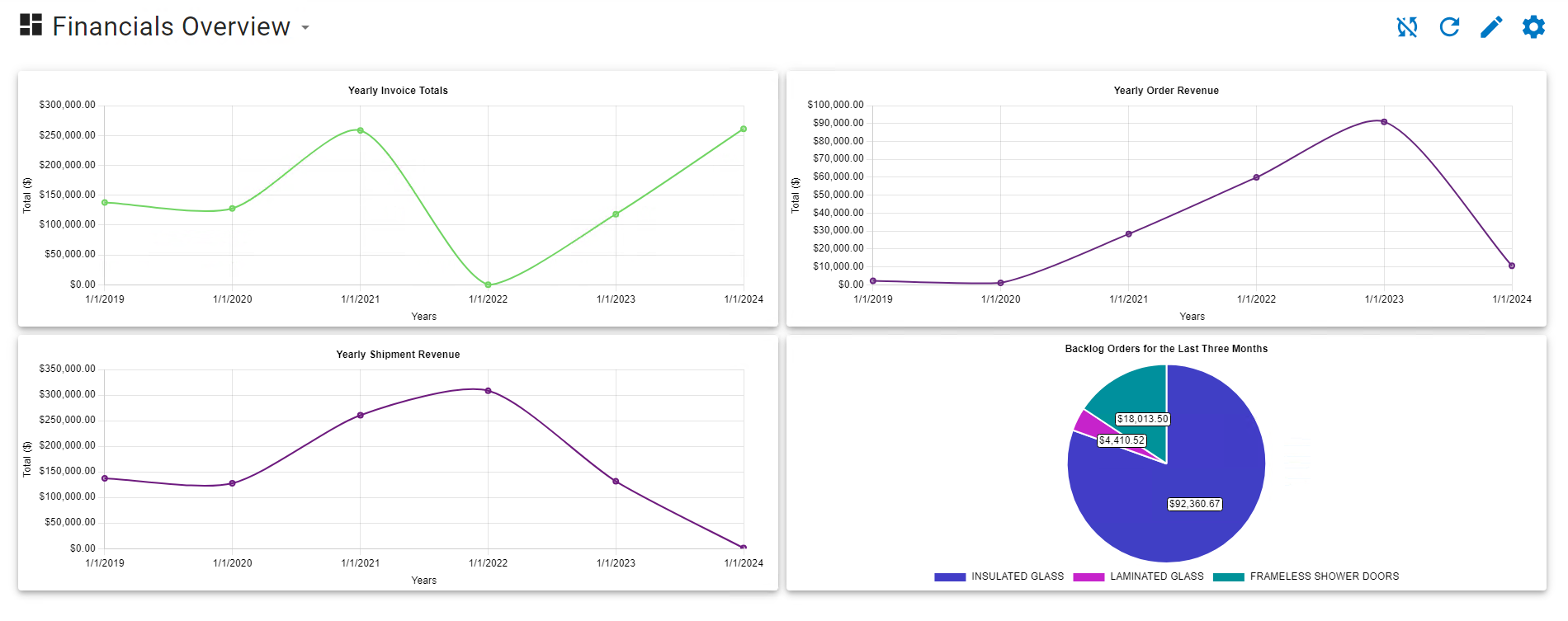

Transform your product production processes with FeneVision's manufacturing ERP software

Developed by manufacturing engineers, FeneVision makes life easy for operators and serves as an ERP for the manufacturing industry to optimize efficiency.

Trusted by industry leaders: See who's excelling with FeneVision

KEY BENEFITS