The evolution of CPQ: From configuration to engineering

Manufacturing

Charles Thompson

In today's rapidly evolving manufacturing landscape, staying ahead of the competition requires more than just efficient production processes. The traditional Configure, Price, Quote (CPQ) model has undergone a significant transformation, now integrating engineering processes to bridge gaps in the value chain and enhance overall efficiency. In this blog, we explore this evolution and its impact on modern manufacturing.

The traditional CPQ model: The CPQ process has long been a cornerstone of sales and manufacturing operations. Traditionally, CPQ tools helped businesses streamline product configuration, accurate pricing, and quick quotation preparation. While effective, these tools often left a gap between the sales process and the actual production, leading to inefficiencies and data inconsistencies.

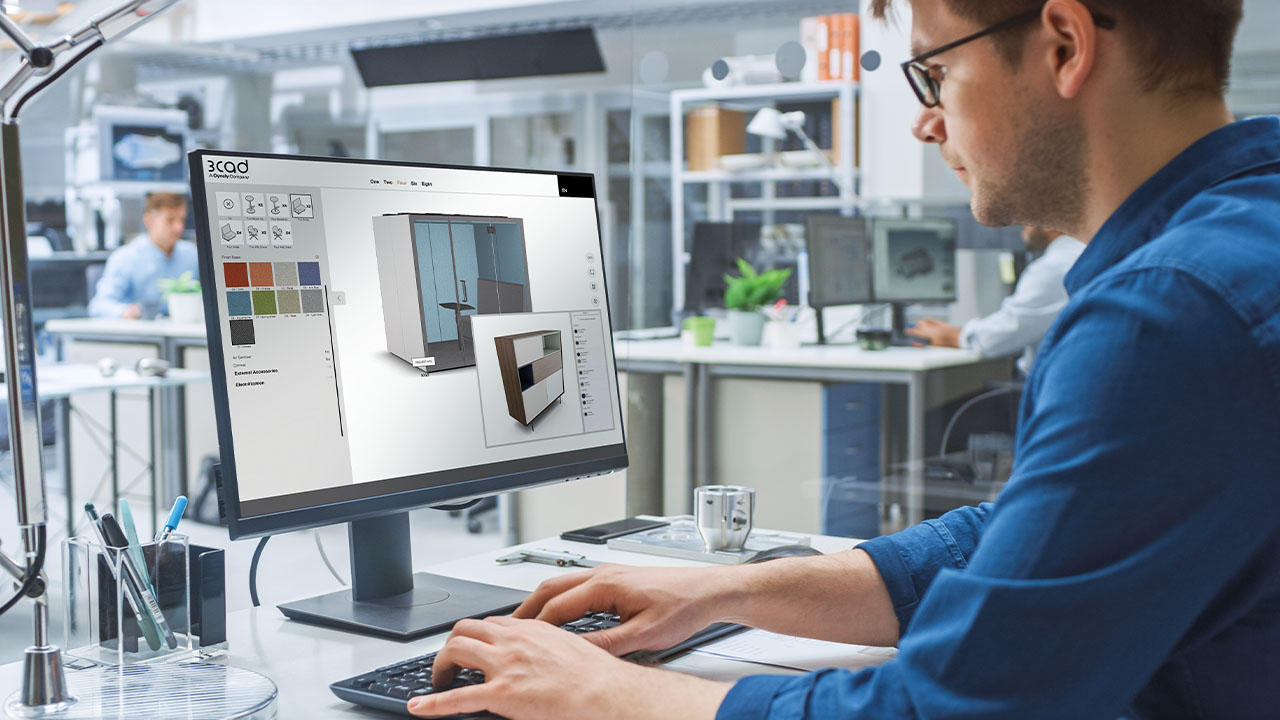

The integration of engineering: The integration of engineering into the CPQ model has been a game-changer. In a recent webinar, Chalrlie Thompson, looked at how Cyncly handles this integration. By adding an engineering component, businesses can ensure that data is consistent, up-to-date, and relevant across all touchpoints, including production. This holistic approach not only enhances the accuracy and reliability of the entire process but also reduces errors and increases process reliability.

Benefits of an integrated CPQ system:

- Enhanced data consistency: With a centralized data hub, all information is managed seamlessly, ensuring that everyone from sales to production is on the same page.

- Improved process reliability: The integration of engineering processes into CPQ tools reduces the likelihood of errors, leading to more reliable production outcomes.

- Increased flexibility: Businesses can quickly adapt to product changes without compromising on speed or reliability, thanks to the flexible nature of integrated CPQ systems.

Real-world applications: During our recent webinar, we showcased several examples of how integrated CPQ systems are being used in the real world. From kitchen and room planners to sofa configurators, the benefits of this integrated approach are evident across various industries.

The evolution of CPQ from a simple configuration tool to an integrated system that includes engineering processes represents a significant advancement in manufacturing technology. By bridging gaps in the value chain and enhancing data consistency, businesses can achieve greater efficiency and reliability in their operations. As the industry continues to evolve, adopting these advanced CPQ systems will be crucial for staying competitive and meeting the demands of modern consumers.

Related blogs

Continuing my journey with the CKCA: Technology and the future of manufacturing

The CKCA is the voice of the Canadian kitchen cabinet industry – one that connects members to inspire progress, innovation and quality. That’s why I’m so happy to be kicking off my second three-year term on the Board of Directors.

The financial benefits of moving to the cloud

Learn about the financial benefits of moving to the cloud, including cost savings, predictable expenses, and reduced maintenance costs.

How to reduce manufacturing lead times and overheads.…

Right now, lead times are longer than ever, pressure on supply chains are putting a huge strain on businesses, and outdated manufacturing processes only exacerbate the problem. But there is a solution, nonetheless.